Say goodbye to the boundaries between the Design Engineers and the Process Engineers, thanks to TopSolid!

It’s a fact: jobs, missions, methods, organization, tools and work habits, … everything seems to oppose the Design Engineers and the Process Engineers, and this happens within many companies. The two entities often do not operate in the same environment and are geographically distant. The lack of interaction between the two departments can sometimes create what we speak of: a “border.”

However, at the time of Industry 4.0, where connectivity and communication in all directions are a strategic necessity. The divide between the IT department through the manufacturing department tends to become a structural issue for the company’s performance.

Let’s discover how the TopSolid digital solution can break down these walls!

1) Design Office VS Process Office: two entities often in opposition within a company

A) Reminder of the missions of each

Design Office

Between engineering and expertise, the mission of the design office revolves around advice, recommendation, and control:

- As a subcontractor, the design office receives and evaluates the feasibility of its entrusted external projects.

- As an integrated department within a manufacturer, the design engineer is responsible for designing projects for their company’s customers.

- Project management also falls within the scope of the design office, which must ensure compliance and traceability.

- Finally, the design office draws up a detailed plan of the design and sends it to the process office.

An innovative mission dedicated to service

Process Office

As the linchpin between the production line and the design office, the process office is responsible for implementing the project from the design office. Its mission has several facets:

Validation of the product’s feasibility after studying elements such as modeling, average dimensions, the geometry of the raw material, or machining assembly.

– Industrialization: it is the study of the means (tools, machines, operators, materials, and equipment) and the solutions to be implemented in the manufacturing process.

– Optimization of work organization (flow management, access, handling, etc.) and machining (time and cost management) to increase productivity.

They monitor machinery and equipment: reporting the need for maintenance or replacement.

– Management of the conformity of the production about the operating procedures (order of operations, tools used, number of people, and time required to carry out each task).

A multi-faceted mission at the heart of which is naturally a strategic need for communication with the design office.

However, often these exchanges between departments are far from being fluid and collaborative.

B) Two worlds that can clash

Creative on one side, functional on the other, and incompatibility of opinions … the reality is hardly subtle. Moreover, the lack of geographical proximity can also factor in.

It so happens that the mission of the Design Office lies in the conception of innovative projects resulting from R&D and consequently presenting a very elaborate technical plan. As such, the department can misrepresent these gratifying aspects, with other departments or subcontractors, thus obscuring how the projects will be industrialized… or even the project feasibility!

However, the Process Office is in charge of industrializing the projects issued by the Design Office … an endemic situation inevitably puts the two departments in opposition, with the Design Office defending innovation and considering the Process Office as the “brakes” on design and creativity … the Process Office, for its part, is not always able to respond favorably to the conceptual project because of a proven lack of solution.

Should we accept this state of affairs as inevitable and “deal with it”?

2) The disadvantages of a two strong opposition between Design Office and Process Office

One thing is sure; the two departments speak the same language: that of 3D modeling, average dimensions, raw materials, machine set-up, and tolerances. There is no shortage of opportunities to exchange information for the smooth running of the project: information needed for industrialization from the design office to the manufacturing office, as well as requests for clarification or revisions before launching the machining, from the manufacturing office back to the design office.

But when the border between the two departments is unbridgeable, a cascade of dysfunctions harmful to the entire organization ensues:

- Waste of time in post-design discussions; each defending their own position.

- Increased risk of errors and data loss if there is no direct exchange interface.

- What about the automatic recovery of part properties and manufacturing characteristics for process office or design office patches?

- And then … we talk about the work atmosphere and motivation?

It is mainly from this cumbersome operation that tensions arise. The loss of time due to a lack of reliability and traceability is the number one enemy of efficiency. A situation that increases standard costs potentially decreases the quality and puts a heavy burden on productivity… not to mention the delay in deadlines!

In short, the exact opposite of what is expected to meet the company’s strategic challenges. How, then, to create the bridge between the design office and the process office to close this counter-productive border?

3) TopSolid: the solution that links the two worlds

Going from a product idea to its industrialization implies, in the current context linked to Industry 4.0, the practice – and if possible, the mastery – of several so-called “basic” requirements:

- a shared thinking process on the global project scale

- a single, reliable, shared information, to frame and manage exchanges

- fluid and factual communication

- a reactive decision-making process

- a genuine and synergistic collaboration

Also, to connect and rally the two departments falls under a logic of synergy of the processes, the objective being to achieve the rigorous management of the geometrical data, the orchestration of the flows, and the collaboration. An ambitious challenge that TOPSOLID takes up with brilliance!

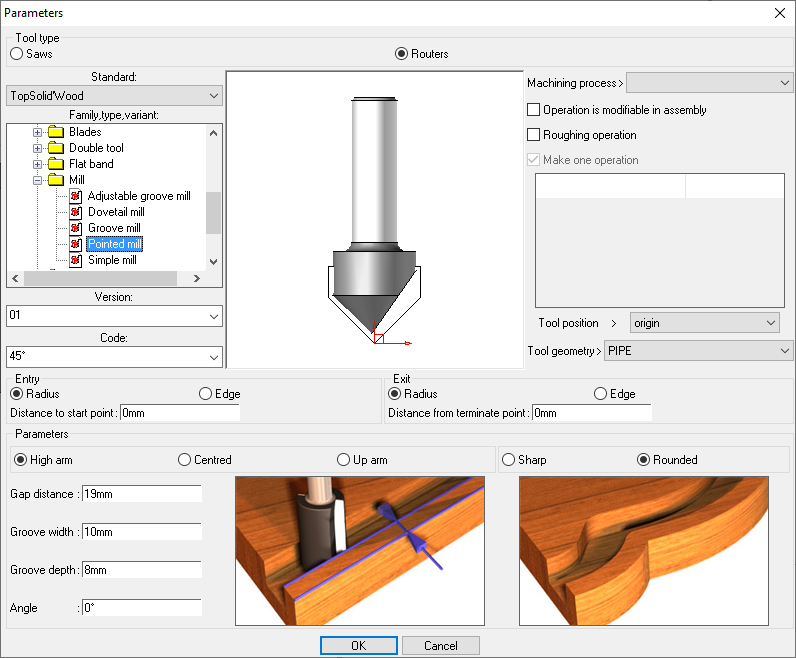

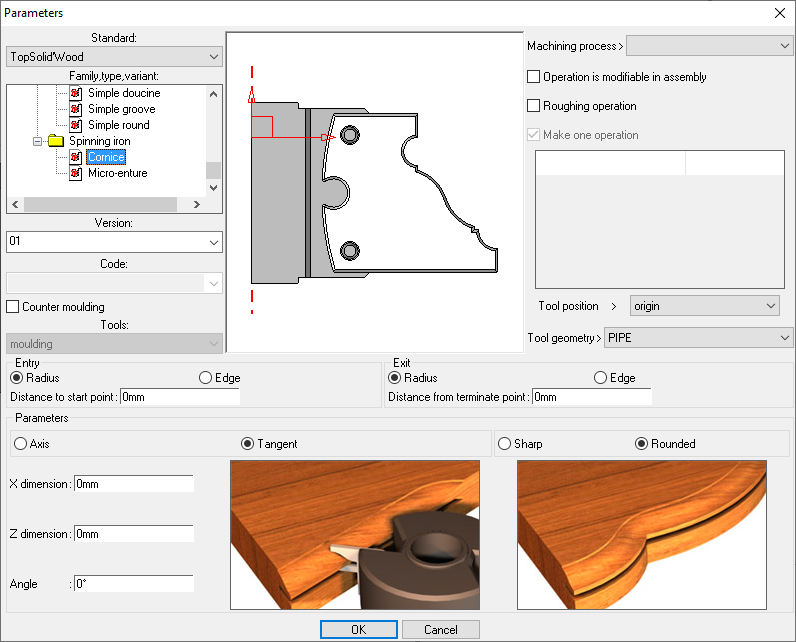

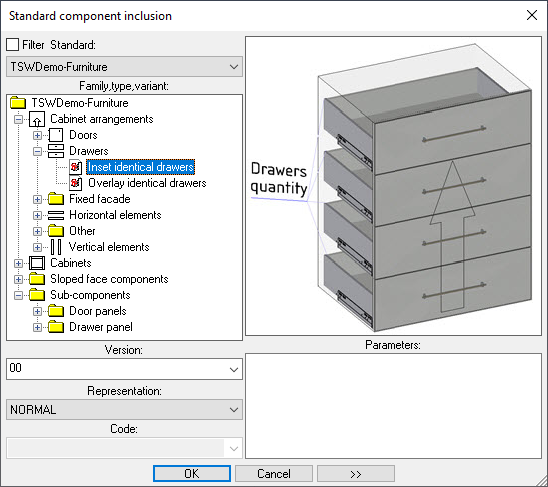

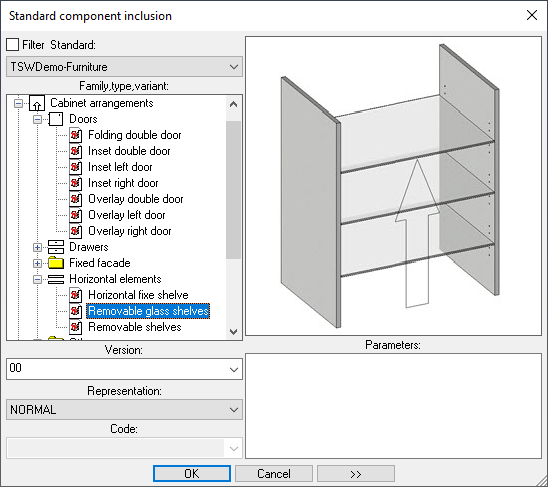

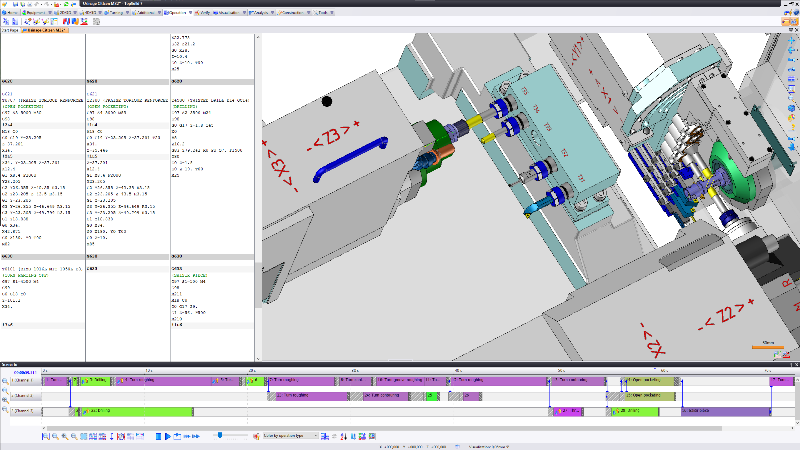

TopSolid’s CAD and CAM solutions are developed on a common database (PDM) with an intuitive user interface and are associative. In addition, the design process integrates all the tools in line with the manufacturing process: the updates of the parts follow in CAM, and the process office can even make slight modifications in agreement with the design office.

With this highly successful CAD/CAM software solution, TopSolid meets the needs of today’s companies:

- Data control: the PDM of the solution manages both the technical data of the design office and the manufacturing office, thus allowing the full recovery of the “parts and manufacturing” characteristics.

- Traceability: TopSolid automatically transfers CAD modifications to CAM, managing common modification indicators.

- Streamline and secure the exchange of information: with TopSolid, file conversions, data entry, and risks linked to errors and data loss are over.

- Efficiency: By merging the design and manufacturing processes, the collaboration between the design and manufacturing departments is improved, thus boosting efficiency and motivation.

- Increased productivity and improved quality.

Suppose this new configuration of the relations between the design office and manufacturing office requires to know how to manage the change (company culture, working methods, tools, …). In that case, it also constitutes the beginnings of digital continuity, so essential to the industrial requirements of tomorrow.

As you understand, fluid and collaborative communication between the design office and the manufacturing office allows the border between the two departments to be erased… And because data volumes are increasing and work flows need to be justified, it has become difficult for industries to pass up a software solution. TopSolid, through its CAM, CAD, PDM, and ERP applications, enables the simplification of exchanges between the design office and the manufacturing office, ensuring the coherence of projects, and secures the design and manufacturing processes while reducing their cost. The time saved is colossal, and the efficiency of the design and manufacturing teams increases. In the end, it is the company’s productivity that improves… A successful challenge!