Why must CAD/CAM solutions become increasingly flexible?

In recent years, the notion of flexibility has become an integral part with companies of all sizes. All resources are considered: flexibility in terms of staff working hours, adaptation of the organization’s personnel according to demand, the flexibility of the software used… In this context, many factors tend to become flexible to coincide with the evolution of industry. Computer-aided design and manufacturing are no exception to the rule! CAD/CAM software used by companies must also become more and more flexible. Here’s how….

Flexibility is a significant challenge for companies

Flexibility, what are we talking about?

Whatever their activity, flexibility is a concept many companies are trying to implement. The objective is to move away from a rigid organization and adapt the organization to the company’s needs at a given moment. In this way, resources are allocated according to the actual activity of the departments, which optimizes their efficiency. Therefore, professionals are required to master a variety of subjects and tools in all areas.

Flexibility is an exceptionally fundamental concept when it comes to CAD/CAM systems. Reducing programming and machining times, improving quality, reducing costs, being competitive with the competition… Many challenges must be met by the teams in charge of CAD/CAM. Flexibility must therefore be translated into concrete terms in the organization of the resources in place, especially personnel. The boundaries between design offices, manufacturing offices, and management must become increasingly narrow. Computer-aided design and manufacturing professionals must collaborate and demonstrate a versatile know how to meet the challenges of their department.

How does flexibility translate into CAD/CAM?

As you will see, lack of flexibility can be a significant issue for companies using CAD/CAM solutions. The concept of this notion of flexibility has many interesting points, two of which are fundamental:

- As soon as the design office considers the way parts are going to be manufactured, the company gains in quality and productivity. Design offices must therefore be aware of manufacturing and production requirements (CAM).

- Likewise, the manufacturing office must consider the way the engineering department designed the parts. This flexibility allows for modifications to be made if necessary to make projects more easily machined. The company then realizes essential productivity gains.

In sum, flexibility in CAD/CAM has four significant benefits:

- Strengthen the links between the Design Offices and the Manufacturing Offices;

- Gaining team cohesion;

- To gain in quality and therefore in customer satisfaction;

- To gain in productivity and therefore in profitability.

However, flexibility in CAD/CAM is not only a matter of teamwork. The CAD/CAM solution used by the company must also be flexible to favor the adaptability of the organization’s resources.

Flexibility is a significant challenge for companies

Flexibility, what are we talking about?

Whatever their activity, flexibility is a concept many companies are trying to implement. The objective is to move away from a rigid organization and adapt the organization to the company’s needs at a given moment. In this way, resources are allocated according to the actual activity of the departments, which optimizes their efficiency. Therefore, professionals are required to master a variety of subjects and tools in all areas.

Flexibility is an exceptionally fundamental concept when it comes to CAD/CAM systems. Reducing programming and machining times, improving quality, reducing costs, being competitive with the competition… Many challenges must be met by the teams in charge of CAD/CAM. Flexibility must therefore be translated into concrete terms in the organization of the resources in place, especially personnel. The boundaries between design offices, manufacturing offices, and management must become increasingly narrow. Computer-aided design and manufacturing professionals must collaborate and demonstrate a versatile know how to meet the challenges of their department.

How does flexibility translate into CAD/CAM?

As you will see, lack of flexibility can be a significant issue for companies using CAD/CAM solutions. The concept of this notion of flexibility has many interesting points, two of which are fundamental:

- As soon as the design office considers the way parts are going to be manufactured, the company gains in quality and productivity. Design offices must therefore be aware of manufacturing and production requirements (CAM).

- Likewise, the manufacturing office must consider the way the engineering department designed the parts. This flexibility allows for modifications to be made if necessary to make projects more easily machined. The company then realizes essential productivity gains.

In sum, flexibility in CAD/CAM has four significant benefits:

- Strengthen the links between the Design Offices and the Manufacturing Offices;

- Gaining team cohesion;

- To gain in quality and therefore in customer satisfaction;

- To gain in productivity and therefore in profitability.

However, flexibility in CAD/CAM is not only a matter of teamwork. The CAD/CAM solution used by the company must also be flexible to favor the adaptability of the organization’s resources.

TopSolid, a flexible solution?

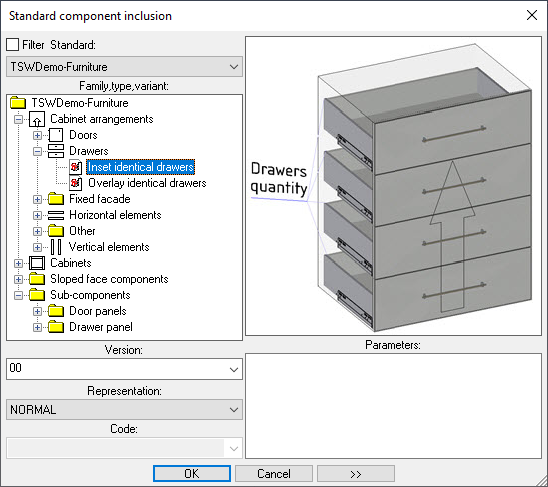

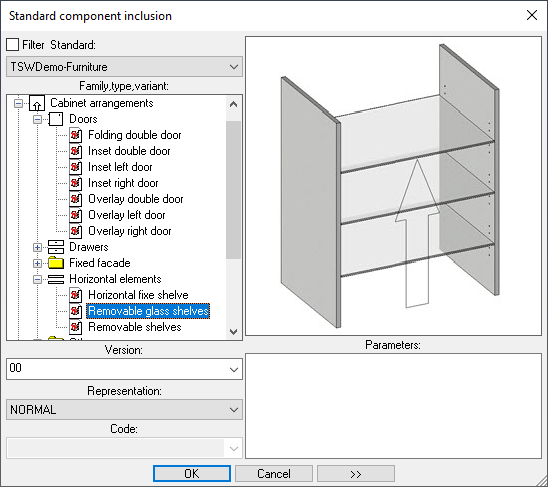

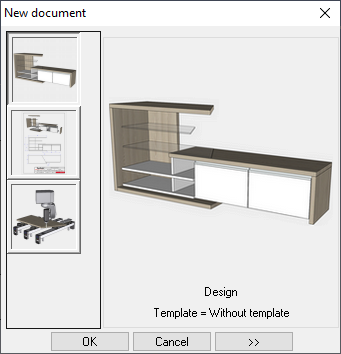

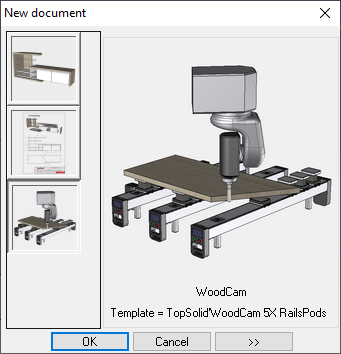

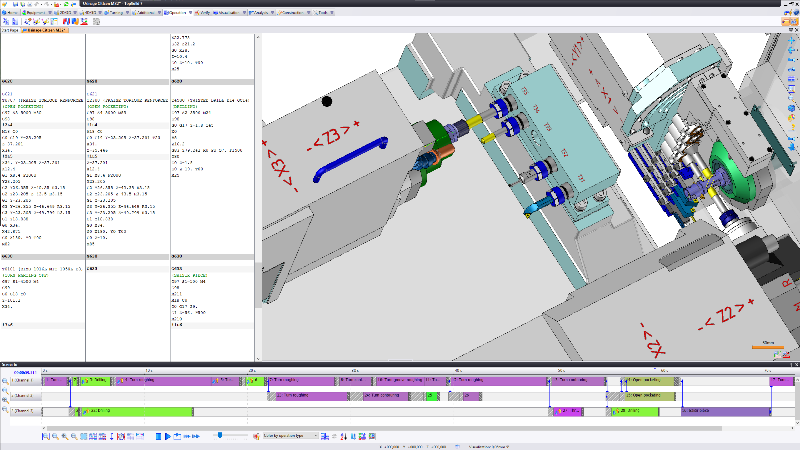

TopSolid is a powerful CAD/CAM solution that offers a fully integrated digital chain. TopSolid contributes to the flexibility of organizations by meeting the challenges of development and adaptability of many companies.

TopSolid, an integrated CAD/CAM-PDM-ERP solution meets the flexibility needs of companies

The CAD and CAM solutions proposed by TOPSOLID are developed in the same environment. This means that they communicate perfectly with each other. The TopSolid CAD/CAM tool guarantees that:

- Changes made in CAD are automatically transferred to CAM.

- The part numbers are associative between CAD and CAM with integral PDM.

- The handling of the CAD tool is fast and straightforward: the manufacturing office can make modifications on the projects of the design office.

- The TopSolid’Erp solution also communicates with the CAD/CAM solution: the management data is entered as soon as the CAD design is completed.

The result: no more re-entering of data and loss of information. Process reliability is guaranteed, and CAD/CAM teams save considerable time.

The flexibility of the TopSolid solution is illustrated!

Legend: Succinct diagram of TopSolid’s workflow

- TopSolid ERP sends manufacturing orders (OFs) directly to TopSolid’SheetMetal CAM in the Job Manager.

- The drawing files (CAD) are automatically retrieved with the part files (parts with cutting or punching operations).

- In the OF(s) sent by the ERP, the following information is provided:

- Part references

- Designations

- The order

- The customer

- The quantity

- The material

- The thickness

- The machine

- …

- TopSolid’SheetMetal CAM gathers this data and creates the nesting.

- TopSolid’SheetMetal CAM refers back to the ERP:

- References of manufactured parts

- The quantities

- The material used

- The times achieved

- …

Conscious of what’s at stake regarding company flexibility, specifically in regard to the CAD/CAM system function, TOPSOLID developed an adaptable and intuitive solution. The collaboration between the engineering offices, the manufacturing offices, and management is thus facilitated. Everyone has the information they need, and processes are optimized and secured. TopSolid Digital Integrated solution offers you the possibility to work with all your collaborators on the same platform and database, capitalizing on the know-how of each one! Would you like to know more? Contact us for more information!